In the potato industry the primary benefits of using a PEF system include higher production yield, enhanced product quality, and the removal of the preheating step, which significantly lowers both energy and water usage.

Since the first industrial PEF plant was installed in the French fries industry in 2010, this technology has become the new standard for potato processing (Mahathir, 2023 and Hill et.al. 2022). The transformation has been remarkable.

- Eliminating the Preheating Step

- Cutting and Processing Efficiency

- Product Quality Improvements

- Yield and Composition Gains

- Fat-Oil, Acrylamide and Energy Reduction

- Economic and Operational Benefits

- Conclusion

- Practical considerations

- Industrial-Scale Equipment

- Find out more about this incredible technology

- Reference

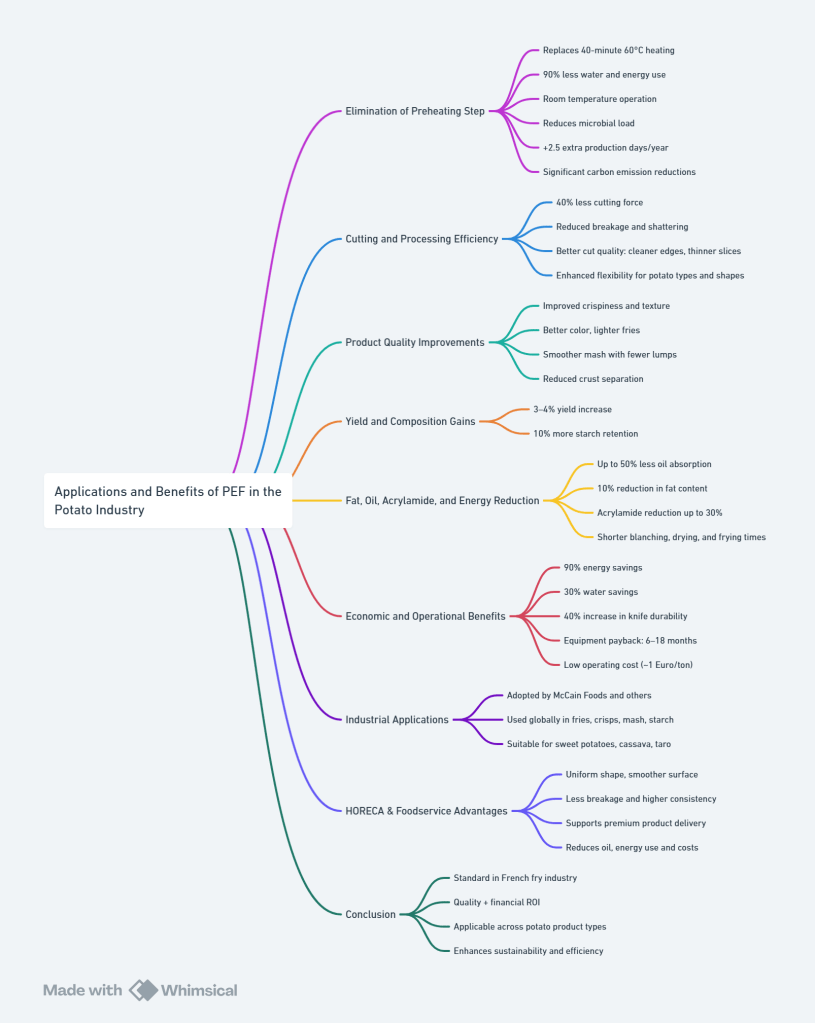

If you’re short on time to read the full text and for a quick overview of the benefits of PEF in the potato industry, refer to this diagram:

Eliminating the Preheating Step

Traditional potato processing required heating potatoes at 60°C for 40 minutes in pre-heaters (Andersson 1994, Laza et al., 2001)—an energy-intensive process that consumed enormous amounts of water and energy; typical hourly consumption ranging from 1.0 to 1.5 kW and 30 liters of water per ton of raw potatoes. Preheating is used in French fry processing to soften and reduce the brittleness of freshly harvested potatoes, minimizing slicing damage and improving the texture and appearance of the final product. In French fry production and other potato processing operations, PEF systems offer a high-performing alternative to traditional preheaters. PEF processing accomplishes the same goals in just 10 seconds while using 90% less water and energy (Siemer et al., 2024). With a PEF system, it is possible to eliminate this preheating step (Hill et.al. 2022).

Additionally, PEF operates at room temperature, which helps lower microbial levels in the process water and reduces ambient heat generation. Since PEF systems eliminate the lengthy startup and shutdown times of conventional preheaters—sometimes up to 45 minutes—producers can gain as much as 2.5 extra production days annually, depending on the operational schedule (Hill et.al. 2022).

At an industrial level, McCain Foods has implemented a Pulsed Electric Field (PEF) system in its potato chip production, achieving significant benefits. The company reports saving around $1 million annually and reducing carbon emissions by nearly 3,990 tons each year. By using PEF instead of coal in the preheating stage, coal usage has decreased by seven tons daily, and freshwater consumption has been lowered by 82% (White et al., 2025).

By inducing cell permeabilization through the application of short, high-voltage pulses, PEF technology improves various process steps including cutting, blanching, drying, and frying. The enhanced efficiency stems from the microscopic pores formed in cell walls, which facilitate better moisture transfer and heat penetration (Siemer et al., 2024). Pulsed Electric Field (PEF) treatment targets cell disintegration, structural modification, and reduction of turgor (osmotic) pressure within potato cells.

Here are the benefits that are associated with PEF application in the potato industry:

Cutting and Processing Efficiency

- Reduced potato breakage or shattering during cutting by making potatoes more flexible (feathering is eliminated); leading to better utilization of the raw material. In French fry production, this leads to longer, thinner fries.

- PEF-treated potatoes require around 40% less force to cut, enabling cleaner cuts, sharper edges, and smoother surfaces.

- Crisp production benefits: the improved slicing results in thinner, smoother surface

- Softer tissue allows more flexibility in using different potato types and shaping methods (Siemer et al., 2024)

For that reason potato processors in the U.S., Canada, Europe, Australia, and New Zealand are adopting PEF pre-treatment to enhance cutting precision and minimize French fry breakage, offering a modern alternative to traditional preheating methods (Balasubramaniam et al., 2022; Lee et al., 2023).

Product Quality Improvements

- Improved crispiness for french fries (Siemer et al., 2024).

- Crisp production benefits: crunchier crisps (due to less retained water).

- Improved colour (Hill et al., 2022). Significantly lighter-colored final products (Siemer et al., 2024)

- No separation of crust on the surface (Hill et al., 2022)

- Mash production benefits: minimizes structural inconsistencies, leading to a smoother mash with fewer lumps and improved overall texture and delivering a more desirable final texture.

Note for french fries: Due to the homogeneous water distribution and enhanced water diffusion, the separation of the crust is less pronounced when applying PEF, which is considered as a quality improvement (Hill et al., 2022).

Yield and Composition Gains

- 10% more starch retained in potatoes. Higher yields due to reduced starch loss (Siemer et al., 2024)

- 3-4% increase in overall yield from the same raw materials (Siemer et al., 2024)

Fat-Oil, Acrylamide and Energy Reduction

- Acrylamide reduction (Hill et al., 2022)

- 10% reduction in fat content due to improved cut quality (Siemer et al., 2024).

- 10% reduction in oil absorption during frying (major cost savings given chips contain up to 35% fat) (Hill et al., 2022; Siemer et al., 2024)

- Others report that PEF pre-treatment reduces frying oil absorption and fat content up to 50% (Balasubramaniam et al., 2022)

- Reduced times for blanching, drying, and prefrying (Balasubramaniam et al., 2022)

- Lower water and energy consumption (Siemer et al., 2024)

Interelated benefits: As already discussed, the reduction in turgor pressure caused by PEF-induced water loss results in a softer texture, making the product easier to cut with less breakage. The smoother surface from cutting also leads to lower oil absorption. Moreover, the open cell structure promotes water evaporation, creating a protective vapor layer that helps prevent oil from penetrating the product. This enhanced evaporation allows for a shorter frying time without changing the final moisture content. Additionally, yield can increase by up to 1.5% thanks to the improved cuttability of the raw material and reduced processing losses (Hill et al., 2022).

Economic and Operational Benefits

- 90% reduction in energy consumption compared to preheaters (Hill et al., 2022).

- 30% reduction in water consumption (Hill et al., 2022).

- 40% increase in knife durability (Hill et al., 2022)

- Reduction in time and energy required for blanching as well as drying and frying (Hill et al., 2022).

- Cost Consideration: On a commercial scale, PEF treatment costs are relatively low—approximately 1 Euro per ton, which translates to around 0.1 Eurocent per kilogram.

- Equipment pays for itself in 6-18 months depending on the setup

Because of all the above, PEF is Seen as Standard in the French fry Industry.

A study demonstrated that using pulsed electric fields as a pre-treatment can effectively enhance the removal of acrylamide precursors from raw potatoes, leading to a reduced acrylamide content in deep-fried potato crisps. A reduction of 30% of acrylamide content was achieved after applying PEF (Genovese et al., 2019).

Conclusion

Potatoes are naturally effective conductors due to their high water content (approximately 80%), consistent density, and significant potassium levels. When exposed to PEF, the permeabilization of cell membranes leads to tissue softening and improved mass transfer properties. This results in higher product consistency, and better processing performance. By reducing turgor pressure, PEF helps standardize the structure of the potato, mitigating issues caused by seasonal or varietal differences.

Frying is a complex process that involves heat and mass transfer, all of which alter the food’s physical and chemical properties. Applying PEF treatment to plant-based foods can enhance these transfers, helping to control the Maillard reaction and support starch gelatinization. This emerging technology has been linked to several benefits in frying, including reduced oil absorption, lower levels of harmful compounds, and greater energy efficiency (Xu et al., 2020; Siemer et al., 2024).

Additionally, innovative cutting styles that enhance yield—such as spiral cuts for French fries or waffle cuts for chips—can be achieved. The improved flexibility of the raw material also enables easier processing of tougher-to-cut varieties like sweet potatoes, cassava, and taro (Xu et al., 2020, Lee et al., 2023, Mahathir, 2023 and Hill et.al. 2022).

For companies processing potatoes for the catering and HORECA (Hotel, Restaurant, and Café) sectors, PEF technology offers a powerful advantage in delivering consistently high-quality products at scale. By softening the potato tissue and enhancing cutting precision, PEF ensures smoother surfaces, uniform shapes, and reduced breakage—ideal for creating premium French fries, crisps, or mashed potatoes that meet the exacting standards of professional kitchens. Faster blanching, drying, and frying times translate into lower energy and oil consumption, helping processors reduce costs while supporting sustainability goals. With improved texture, reduced oil absorption, and extended shelf-life, PEF-treated potato products provide chefs and foodservice operators with reliable, high-performing ingredients that elevate the final dish and streamline kitchen operations. Applicable Products: French fries, frozen and chilled potato products, potato crisps, mashed potatoes, and starches.

The use of Pulsed Electric Field (PEF) technology offers a wide range of quality and processing advantages, making it a standard in the potato processing industry. It’s important to distinguish between quality-related benefits—such as reduced acrylamide levels and improved color—which do not directly impact the return on investment (ROI), and tangible process and financial benefits, like reduced water usage and increased product yield. In French fry production, the primary advantage of PEF pre-treatment is its ability to replace traditional preheating methods, cutting energy consumption by up to 90% and resulting in a payback period of less than two years. In chip production, the main cost savings come from increased yield and higher processing capacity. This is why PEF was first adopted in French fry processing, then in chips industry. However, as product quality becomes increasingly important, PEF systems are now more frequently used in chip production as well. It’s essential to note, though, that for chips, simply adding a PEF system is not enough—downstream steps like cutting and frying must also be adjusted to fully realize the benefits and ensure a high-quality end product (Hill et.al. 2022).

Practical considerations

When the potatoes arrive at the factory, they are sorted, washed, and peeled using either abrasive or steam methods. Those not suitable for French fry production are diverted into a separate stream for use in products like mashed potatoes or flakes. Peeling can occur either before or after PEF treatment, as the process does not affect peeling efficiency. However, peeling beforehand helps minimize the amount of dirt entering the PEF system, resulting in lower water usage. As a result, most modern processing lines position the PEF unit after the peeling stage (Hill et al., 2022).

Industrial-Scale Equipment

Industrial PEF systems, supporting processing capacities from 1,000 kg/h up to 50,000 kg/h (110,000 lb/h). These systems handle a wide range of potato sizes with minimal limitations. The most powerful units, rated up to 100 kW, can process 70 to 80 tons of potatoes per hour (154,000–176,000 lb/h), catering to large-scale operations seeking enhanced efficiency, higher output, and reduced cost of ownership.

Find out more about this incredible technology

If you would like to read more about PEF technology and its other applications read this post here.

Reference

Andersson, A., Gekas, V., Lind, I., Oliveira, F., Öste, R. and Aguilfra, J.M., 1994. Effect of preheating on potato texture. Critical Reviews in Food Science & Nutrition, 34(3), pp.229-251.

Balasubramaniam, V. M., Janahar, J., & Jin, T. (2022, November 9). Pulsed electric field processing applications in the food industry (Fact sheet No. FST‑FABE‑1002). Ohio State University Extension. Ohioline. Retrieved from https://ohioline.osu.edu/factsheet/fst-fabe-1002

Genovese, J., Tappi, S., Luo, W., Tylewicz, U., Marzocchi, S., Marziali, S., Romani, S., Ragni, L., & Rocculi, P. (2019). Important factors to consider for acrylamide mitigation in potato crisps using pulsed electric fields. Innovative Food Science & Emerging Technologies, 55, 18–26. https://doi.org/10.1016/j.ifset.2019.05.008

Hill, K., Ostermeier, R., Töpfl, S., Heinz, V. (2022). Pulsed Electric Fields in the Potato Industry. In: Raso, J., Heinz, V., Alvarez, I., Toepfl, S. (eds) Pulsed Electric Fields Technology for the Food Industry. Food Engineering Series. Springer, Cham. https://doi.org/10.1007/978-3-030-70586-2_9

Laza, M., Scanlon, M. G., & Mazza, G. (2001). The effect of tuber pre-heating temperature and storage time on the mechanical properties of potatoes. Food Research International, 34(8), 659–667. https://doi.org/10.1016/S0963-9969(01)00086-2

Lee, P.Y., Leong, S.Y. and Oey, I., 2024. Prospects of pulsed electric fields technology in food preservation and processing applications from sensory and consumer perspectives. International Journal of Food Science and Technology, 59(10), pp.6925-6943.

Mahathir, M. (2023, June 1). Reducing the impact. Food Science and Technology, 37(2), 46–49. https://doi.org/10.1002/fsat.3702_11.x

PEF for Potato Treatment., https://www.pulsemaster.us/pef-products/potato-products#:~:text=In%20potato%20processing%2C%20such%20as,%2C%20drying%2C%20and%20frying%20processes.

Siemer, C., Hill, K., Schröder, S., Kirchner, M., & Töpfl, S. (2024, February). Application of pulsed electric fields (PEF) in the food industry (2nd ed., DLG Expert Report 02/2024). DLG e.V. https://www.dlg.org/en/mediacenter/dlg-expert-reports/nutrition/dlg-expert-report-02-2024-application-of-pulsed-electric-fields-pef-in-the-food-industry

Xu Z, Leong SY, Farid M, Silcock P, Bremer P, Oey I. Understanding the Frying Process of Plant-Based Foods Pretreated with Pulsed Electric Fields Using Frying Models. Foods. 2020 Jul 17;9(7):949. doi: 10.3390/foods9070949. PMID: 32709057; PMCID: PMC7404407.