As consumer demand grows for minimally processed foods that retain fresh-like qualities, and as sustainability concerns drive the need for more efficient processing methods, Pulsed Electric Field (PEF) technology is positioned to play an increasingly important role across the entire food industry.

From the French fries you eat to the juice you drink, from the wine you enjoy to the olive oil you cook with, PEF is working behind the scenes to deliver better quality, safer products while using fewer resources.

Imagine being able to preserve food longer, extract more nutrients, and improve texture—all while using less energy and maintaining better quality than traditional food processing methods (Lee et al., 2023, White et al., 2025). This is exactly what PEF technology accomplishes, and it’s quietly transforming the food industry around the world.

Use the table of contents below to navigate this post more easily:

- A pulse about PEF’s History

- What is PEF Technology? How Does PEF Actually Work?

- Summary of Processing Efficiency Improvements

- Overview of applications of PEF in Food InduStry

- PEF as a Gentle Microbial Inactivation Method

- Transforming the Potato Industry

- Revolutionizing Vegetable Processing

- Extracting Nature’s Valuable Components

- Wine Production Innovation

- Premium Olive Oil Production

- Meat Processing Innovations

- Citrus and Fruit Processing

- Biotechnology Applications

- The Future of Food Processing

- REFERENCES

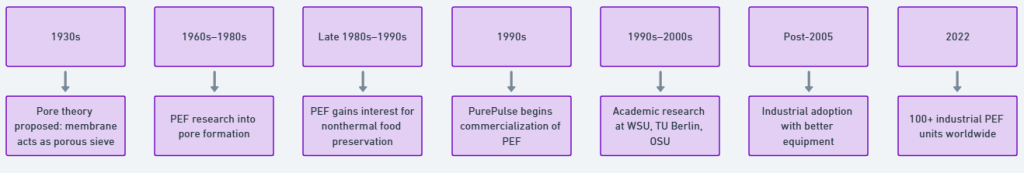

A pulse about PEF’s History

The idea that pores could form in the plasma membrane was first proposed in the 1930s, with the membrane thought to act like a porous sieve, allowing molecules to pass based on their solubility in membrane components. Experimental evidence supporting pore formation by external electric fields emerged in 1958, when reversible electrical breakdown was observed in the membrane of a Ranvier node. This finding led to extensive research into pore formation under pulsed electric fields during the 1960s to 1980s.

Pulsed Electric Field (PEF) technology, researched since the 1960s, gained momentum in food processing in the late 1980s–1990s due to demand for nonthermal preservation methods. Early commercialization efforts were led by PurePulse Technologies, followed by significant academic research at institutions like Washington State University (WSU), TU Berlin, and Ohio State University. PEF showed promise for microbial inactivation and enhancing mass transfer in food processing. Industrial adoption increased after 2005 with better equipment. EU-funded projects and global collaborations, such as COST Action TD1104 and ISEBTT, further advanced PEF applications (Raso et al., 2022).

Several EU-funded projects have supported these advancements. Today, PEF is used commercially in preserving juices, enhancing extraction, and processing plant-based foods, with over 100 industrial units worldwide, as of 2022 (Raso et al., 2022).

What is PEF Technology? How Does PEF Actually Work?

To understand PEF, we need to look at what happens at the level of cells. Electroporation, also known as electropermeabilization, is a phenomenon where exposure of cells or tissues to short, high-voltage electric pulses temporarily or permanently increases the permeability of their membranes (described in more detail below). The mechanism behind electroporation involves the formation of aqueous pores in lipid bilayers and may also include chemical and protein-level membrane alterations. The process works by applying powerful electrical pulses—ranging from 20,000 to 80,000 volts per centimeter for liquids, and 1,000 to 8,000 volts for solid foods—for just milliseconds or microseconds. These brief electrical treatments can be applied up to 3,000 times per second, ensuring complete and uniform treatment (Raso et al., 2022; White et.al., 2025).

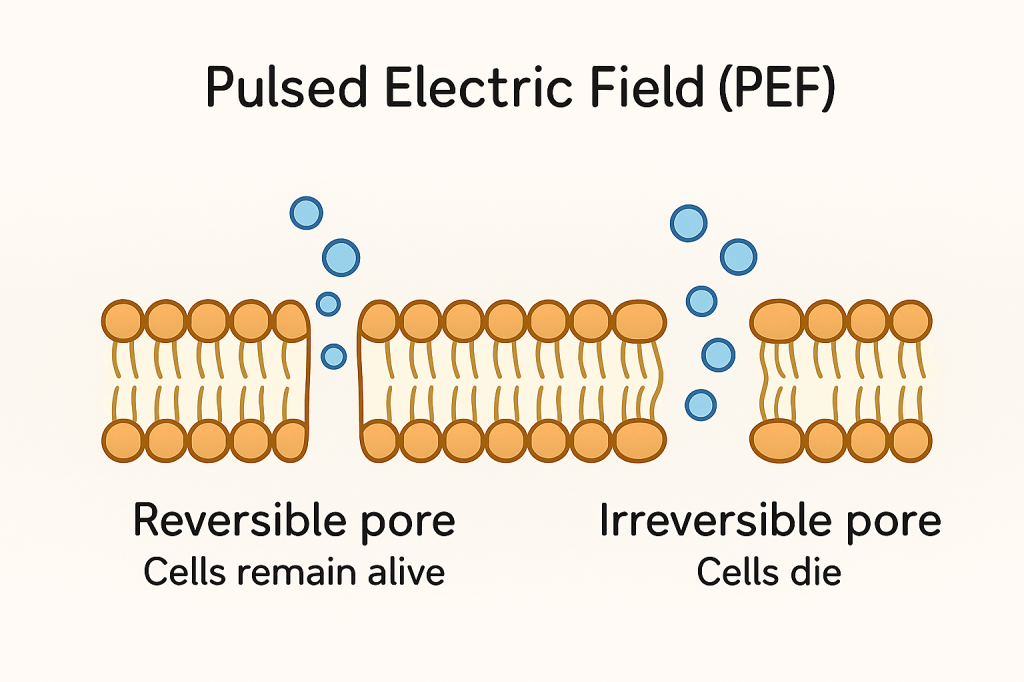

The process of electroporation can be reversible—allowing cells to recover after substances like salt in brine, drugs or genes are delivered—or irreversible, leading to cell death, all of which are useful in diverse disciplines including cancer treatment and food processing.

This effect, discovered in the late 1950s, has since become a central technique in fields such as biomedicine, food science, and biotechnology. Although various terms (e.g., electropulsation, PEF, PFA) are used across disciplines, they all refer to the same core principle of electric-field-induced membrane changes. Applications range from tumor ablation, gene therapy, and electrochemotherapy in medicine, to enhanced juice extraction, improved drying, and non-thermal pasteurization in the food industry. Electroporation’s effectiveness depends on pulse intensity, duration, and how the membrane responds, and it often works best when combined with other techniques like heat, pressure, or UV light, especially for microbial inactivation and food preservation (Raso et al., 2022).

Pulsed Electric Field processing is an innovative food treatment method that uses short bursts of high-voltage electricity to improve food processing and preservation. Think of it as giving food a precisely controlled electrical “shock” that opens up tiny doorways in cell walls, allowing us to achieve remarkable results without the harsh treatments traditionally required.

Every living cell—whether it’s a pathogen in juice or a potato cell or meat muscle cell—is surrounded by a membrane made primarily of fatty molecules called phospholipids. This membrane acts like a natural insulator, maintaining the cell’s internal electrical charge.

Pulsed Electric Field (PEF) processing utilizes electroporation to alter cell membranes, specifically by creating transient pores or channels in the lipid bilayer. This process, involves exposing cells to short, high-voltage pulses of electricity, leading to an increase in cell membrane permeability. Depending on the intensity and duration of treatment, we can create either:

- Reversible pores: These are water-friendly openings that close automatically after treatment, leaving cells alive but temporarily more permeable

- Irreversible pores: With higher intensity treatment, these become permanent openings that cannot close, ultimately killing the cell (Demir et al. 2023)

This controllability is what makes PEF so versatile:

- gentle treatment for extraction applications like in the case of juices or mass transfer as in the case of drying, re-hydration or brining and other applications.

- intense treatment for microbial inactivation.

Pulsed electric field technology offers diverse solutions for enhancing both processing efficiency and final product quality across multiple food industry sectors. In the past decade, the food industry’s push for energy efficiency and sustainability has driven research into PEF (Pulsed Electric Field) applications. PEF helps lower energy use and processing costs in various operations like olive oil malaxation, wine maceration, tomato peeling, and juice production. It’s also increasingly used to recover valuable compounds (e.g., proteins, pigments, lipids) from microbial cells and food waste for food, cosmetic, pharmaceutical, and biofuel industries.

Summary of Processing Efficiency Improvements

Numerous research studies have investigated the use of pulsed electric field (PEF) technology as an emerging method for processing a wide range of food products. These include fruit and vegetable juices, dairy items, liquid eggs, tiger nut milk, kombucha, red wine, soymilk, soy protein isolate, potatoes, oilseeds, mixed drinks, and byproducts from fruits and vegetables.

Generally, PEF applications in food processing fall into two main categories: (i) high-intensity pulsed electric field (HIPEF) treatments aimed at preserving liquid foods, and (ii) moderate-intensity pulsed electric field (MIPEF) treatments used to enhance the extraction of bioactive compounds from plant-based sources or to improve the efficiency of other processes such as drying, frying, oil extraction, thawing, and winemaking. In both cases, the effects on food quality are typically minimal, though they depend on the specific treatment parameters and the characteristics of the food (Raso et al., 2022).

About HIPEF

It is essential to note that only uniform, particle-free, and bubble-free liquids can undergo high-intensity pulsed electric field (HIPEF) treatment, as the presence of gas bubbles or suspended solids can lead to dielectric breakdown during the process. The effectiveness of HIPEF is mainly determined by several factors: (a) the strength of the electric field and the duration of treatment, (b) the type of microorganism or enzyme targeted, and (c) the properties of the liquid being treated (Raso et al., 2022).

This effect can be either reversible or irreversible, depending on the treatment parameters. Although HIPEF has shown strong potential for inactivating microorganisms, it is not suitable for sterilization, as it cannot eliminate spores unless used alongside heat treatments. However, it is considered a promising method for pasteurizing acidic products like fruit juices and fruit-based beverages, offering benefits such as extended shelf life, preserved fresh-like qualities, and enhanced functional properties compared to heat-pasteurized alternatives (Raso et al., 2022).

To effectively reduce harmful and spoilage microorganisms in fruit and vegetable juices, electric field strengths in the range of 20 to 45 kV/cm are typically applied. Under these conditions, HIPEF can inactivate various pathogens without significantly altering the sensory or nutritional quality of the food (Raso et al., 2022).

When it comes to enzyme inactivation, HIPEF usually requires higher energy levels than those used for microbial inactivation, as enzymes tend to be more resistant. The process primarily alters the enzyme’s structural levels—secondary, tertiary, and quaternary—affecting its activity. Factors such as electrochemical interactions, the enzyme’s physicochemical traits, treatment settings, and the composition of the medium (including pH, viscosity, conductivity, and ionic strength) all influence the degree of enzyme inactivation (Raso et al., 2022).

HIPEF may either enhance, suppress, or leave enzyme activity unchanged, depending on the nature of the enzyme and the treatment conditions. Most research has focused on using HIPEF to inactivate enzymes, with the goal of extending product shelf life. Studies have shown that HIPEF can significantly reduce the activity of several enzymes related to food quality, such as alkaline phosphatase, peroxidase, lipoxygenase, lipase, protease, pectin methylesterase, and polyphenol oxidase (Raso et al., 2022).

Beyond microbial safety and enzyme inactivation, HIPEF is also effective at preserving the overall quality of food. It maintains key attributes like flavor, color, and nutritional value, and in some cases, it can even enhance the levels of beneficial compounds in the food (Raso et al., 2022).

About MIPEF

Moderate-intensity pulsed electric field (MIPEF) treatments operate on the same basic principles as high-intensity PEF (HIPEF) but use lower electric field strengths, typically below 20 kV/cm. Unlike HIPEF, MIPEF can be applied to solid foods that are suspended in a liquid medium. The treatment causes cell membranes to become permeable—either temporarily or permanently—depending on the specific conditions applied (Raso et al., 2022).

MIPEF induces non-thermal cell permeability and stress responses in plant-based foods. These effects can stimulate the production of plant secondary metabolites, enhance the selective extraction of high-value compounds with high purity, and improve mass transfer rates. As a result, MIPEF can increase the efficiency of various food processing operations such as osmotic dehydration, drying, freezing, and the extraction of oil, juice, and bioactive components from food and by-products. It can be used as a pre-treatment or as an aid to other processing techniques, enabling the creation of high-quality food products (Raso et al., 2022).

Compared to traditional methods, MIPEF-assisted processes offer several advantages, including reduced processing times, lower solvent usage, and less intensive extraction conditions. These improvements translate to lower energy consumption and a reduced environmental footprint. Additionally, MIPEF helps preserve heat-sensitive compounds, resulting in products with better functional properties and added nutritional value (Raso et al., 2022).

Extensive research has demonstrated MIPEF’s effectiveness across a wide range of food matrices. For example, treatments ranging from 0.25 to 1 kV/cm in white grapes have been shown to speed up juice extraction, increase yield, and enhance the quality of the juice, while minimizing oxidation—a common issue in conventional extraction. Similarly, processing apple mash at 3 kV/cm led to a noticeable increase in antioxidant content in the resulting juice, attributed to the greater release of phenolic compounds. In another case, rapeseeds treated at 5–7 kV/cm showed significantly higher oil yields and improved levels of health-promoting compounds (Raso et al., 2022).

MIPEF has also gained traction as a pre-treatment in industrial applications. In potato processing, for instance, it has been integrated at a commercial scale in over 50 installations worldwide. Results show improved color and texture in products like French fries, along with a roughly 10% reduction in oil uptake during frying. These successes have sparked interest among other sectors, such as fruit processors, who see MIPEF as a promising method to enhance the quality of dried fruits and juice-based beverages (Raso et al., 2022).

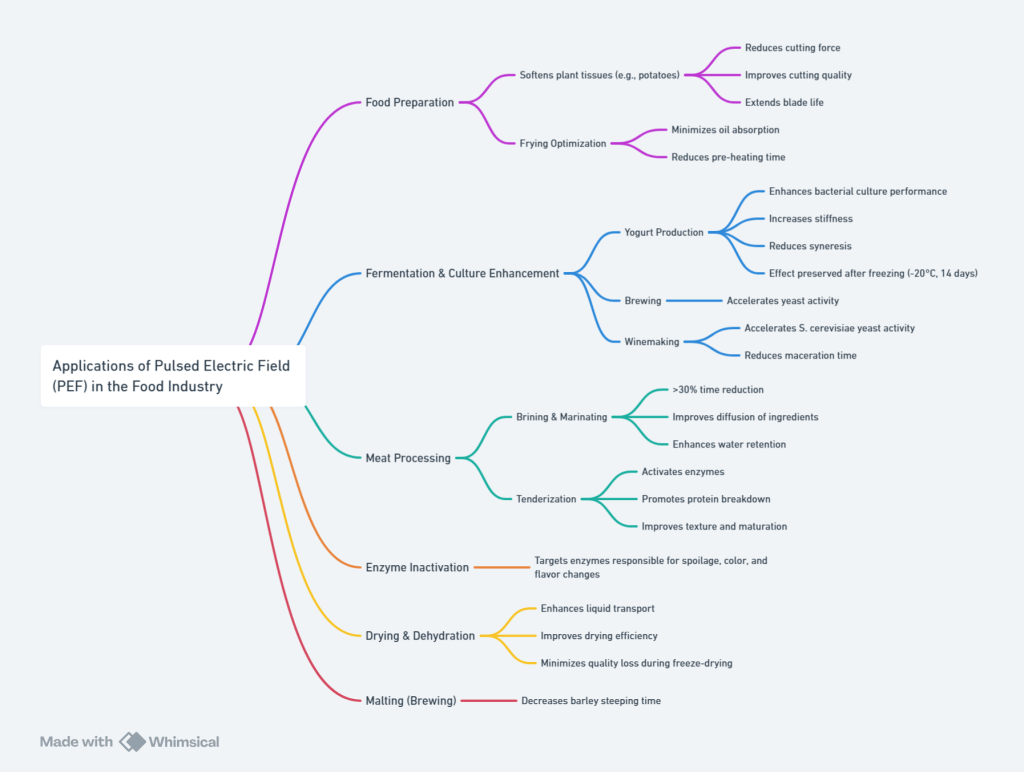

Overview of applications of PEF in Food InduStry

The image below summarizes the applications (described in more detail below) of PEF in the Food Industry. Click on the image to enlarge it for easier reading:

- Food Preparation: Softens plant tissues, reducing cutting force needed for foods like potatoes ensuring better cutting and reducing food waste. It also extends blade life (Lee et al., 2024).

- Frying Optimization: Minimizes oil absorption in vegetable-based products and shortens pre-heating requirements (Lee et al., 2024).

- Enhances bacterial cultures in yogurt production for improved process control: increase stiffness and reduce syneresis in the final yogurt. This effect of the PEF-pre-treated culture was partially preserved even after flash-freezing and storing the culture at −20 °C for 14 days (Stühmeier-Niehe et al., 2023).

- Accelerates yeast activity in brewing applications

- Accelerates activity of wine S. cerevisiae yeast inocula (Mattar et al., 2015)

- Meat Processing: Speeds up brining and marinating (>30% time reduction) by improving ingredient diffusion, reducing processing time, and enhancing final product qualities like water retention (Tomasevic et al., 2023).

- Tenderization: Activates natural enzymes and promotes protein breakdown for improved meat texture and maturation. (Tomasevi et al., 2023)

- Effectively inactivate various enzymes responsible for undesirable changes in food, such as spoilage, colour or flavor alteration.

- Brewing: Decreases barley steeping time during malting (Polachini et al., 2023)

- Facilitates liquid transport for more effective drying processes

- Minimizes quality degradation during freeze-drying operations

- PEF can significantly reduce the maceration time during winemaking (Feng et al., 2022).

PEF as a Gentle Microbial Inactivation Method

Pulsed Electric Field (PEF) pasteurization offers an advantage over traditional heat treatment by better preserving bioactive compounds. For instance, tomato juice and orange juice treated with PEF contained higher levels of phenolic acids and flavonoids compared to those subjected to conventional thermal processing.

Conventional methods of food preservation that work by preventing microbial growth typically involve controlling temperature, reducing water activity, acidifying the product, adding chemical preservatives, or using modified atmosphere packaging. However, because certain harmful microorganisms can cause illness even in very small numbers, simply inhibiting their growth is not always enough to guarantee food safety. In such cases, technologies that actively inactivate microorganisms are required.

Among these, heat treatment remains the most widely used method due to its simplicity and effectiveness. Pasteurization eliminates vegetative pathogens, while sterilization through heat destroys microorganisms, including spores, that could survive in non-refrigerated conditions and pose serious health risks.

However, the downside of thermal processing is its negative impact on the food’s nutritional value and sensory qualities. These include protein degradation, color changes, and the loss of vitamins and flavor compounds. As a result, heat treatments are not ideal for producing the fresh-like, minimally processed foods that consumers increasingly prefer—products that are natural and free from artificial preservatives.

This consumer demand has led to a growing interest in nonthermal preservation methods, which aim to extend shelf life by inactivating harmful and spoilage-causing microorganisms while maintaining the food’s nutritional and sensory integrity. To be viable for industrial use, these technologies must also be cost-effective.

PEF has been shown to effectively inactivate vegetative cells of bacteria, yeasts, and molds. However, it is less effective against bacterial spores at or near room temperature. For PEF to be accepted as a replacement for traditional pasteurization, it must be proven to deliver a comparable level of microbial safety. This requires extensive research to understand how PEF inactivates microbes, identify the key variables that influence its effectiveness, and establish inactivation kinetics. It is also essential to evaluate the technology’s impact on microorganisms that are significant from a public health perspective, particularly those that are most resistant to PEF treatment (Raso et al., 2022).

After pulsed electric field (PEF) treatment, microbial cells can experience a range of outcomes:

- Non-Electroporated Cells:

Some cells are not affected by the electric field and remain structurally intact. These cells are classified as non-injured and survive the treatment without changes. - Electroporated Cells:

These cells undergo membrane permeabilization, which can be either:- Reversible Electroporation:

Pores formed in the cell membrane reseal over time. These cells may initially be injured but can potentially recover. The recovery outcome depends on environmental conditions:- Under optimal recovery conditions, the cells may repair and return to a viable state.

- Under adverse conditions, cells may die or become stressed, a state marked by uncertain survival.

- Irreversible Electroporation:

The pores do not reseal, resulting in membrane breakdown and leading to cell death.

- Reversible Electroporation:

- Intermediate Outcomes (Hypothesized):

Some cells may transition into a stressed state or experience electro-deactivation, where they appear intact but are functionally compromised and may eventually die. These outcomes are still being explored and represent new or not fully understood concepts (Raso et al., 2022).

Overall, the fate of a cell post-PEF depends on whether it is electroporated and, if so, whether the electroporation is reversible and followed by favorable recovery conditions (Raso et al., 2022).

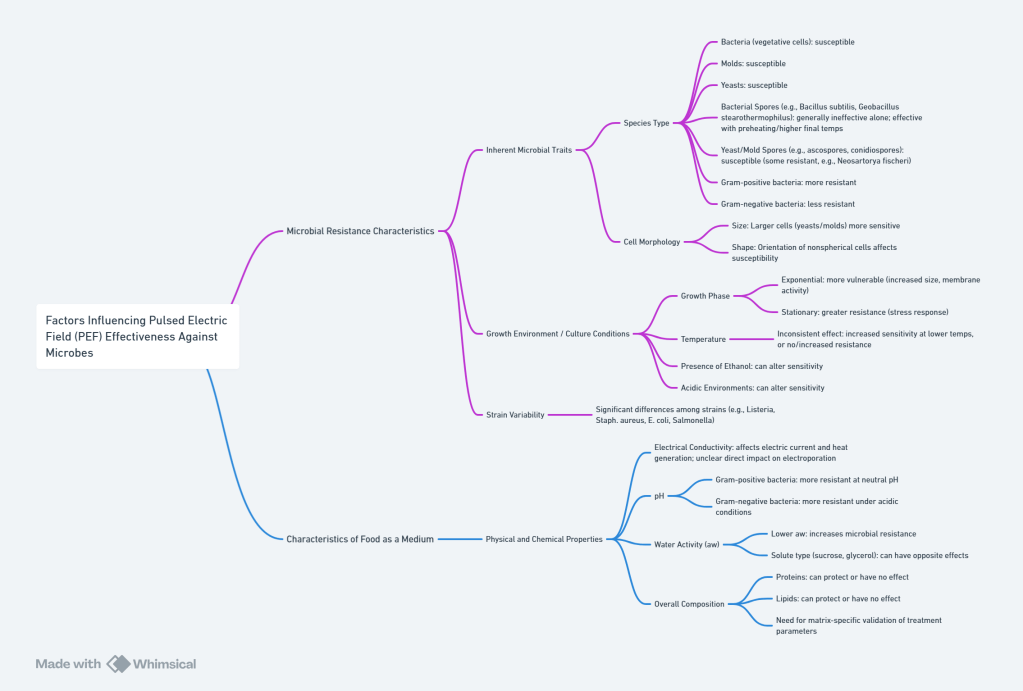

Factors influencing PEF’s effectiveness against microbes

The image below summarizes the factors (described in more detail below) influencing the effectiveness of PEF in microbial inactivation. Click on the image to enlarge it for easier reading:

Microbes resistance characteristics

Microbial resistance to pulsed electric fields (PEF) largely depends on inherent microbial traits, including the species type, cell morphology (size and shape), and growth environment. Additionally, the resistance exhibited by microbes to PEF treatment does not necessarily align with their resistance to other methods of microbial inactivation .

For many years, it has been recognized that while PEF is quite effective at inactivating vegetative cells of bacteria, molds, and yeasts, it is generally ineffective against bacterial spores. This resistance is likely due to the complex structure of spore envelopes, particularly the cortex, which may inhibit electroporation. However, more recent research has shown that bacterial spores such as those from Bacillus subtilis and Geobacillus stearothermophilus can be inactivated when PEF is combined with moderate preheating and higher final temperatures.

As for nonbacterial spores, some yeast and mold spores, like ascospores and conidiospores, are susceptible to PEF, although certain ascospores, such as those from Neosartorya fischeri, have demonstrated resistance. Resistance to PEF is influenced not only by the type of microorganism—Gram-positive bacteria tend to be more resistant than Gram-negative—but also by significant variability among strains within the same species. For example, different strains of Listeria monocytogenes, Staphylococcus aureus, Escherichia coli, and Salmonella typhimurium can show a wide range of inactivation levels, from under 1.0 to as much as 4.0 Log₁₀ reductions. However, in some cases, such as pigmented and non-pigmented enterotoxigenic strains of S. aureus, similar resistance levels have been observed. Overall, the differences in PEF resistance between species are generally greater than the differences among strains within a species.

Microbial resistance to PEF is influenced by several intrinsic and environmental factors, with cell size and shape playing a key role—larger cells like yeasts and molds are generally more sensitive, while the orientation of nonspherical cells within the electric field can affect their susceptibility. Culture conditions also impact resistance; cells in the exponential growth phase are typically more vulnerable due to increased size and membrane activity, whereas those in the stationary phase often show greater resistance due to stress response mechanisms.

The effect of temperature is inconsistent, with some evidence suggesting increased sensitivity at lower temperatures due to changes in membrane composition, while other findings show no effect or even increased resistance. Additional factors like ethanol presence or acidic environments can also alter PEF sensitivity, sometimes enhancing or reducing resistance depending on treatment conditions. Overall, microbial response to PEF is complex and influenced by a combination of cellular traits and environmental conditions (Raso et al., 2022).

Characteristics of Food as a Medium that affects PEF’s effectiveness

The characteristics of the treatment medium play a crucial role in determining microbial sensitivity to PEF. Food products vary greatly in their physical and chemical properties, which can influence how effective PEF is at inactivation.

Key factors such as electrical conductivity, pH, water activity (aw), and the overall composition of the medium can alter treatment outcomes. For instance, electrical conductivity affects the electric current and heat generation, though its direct impact on electroporation is unclear due to interactions with other variables. pH influences microbial resistance differently depending on the type of microorganism; Gram-positive bacteria are generally more resistant in neutral pH, while Gram-negatives tend to resist better under acidic conditions. This behavior may relate to each group’s ability to recover from sublethal damage.

Water activity also affects resistance, with lower aw typically increasing microbial resistance due to cell shrinkage and membrane changes; however, the solute used to adjust aw (like sucrose or glycerol) can lead to opposite effects. Lastly, components such as proteins and lipids in the medium may either protect or have no influence on microbial cells during PEF, depending on conditions like pH, making it necessary to validate treatment parameters specifically for each food matrix (Raso et al., 2022).

Overall

PEF is not effective in deactivating bacterial spores on its own. However, ongoing studies indicate that combining PEF with heat may help inactivate these spores, although further in-depth research is necessary before it can be considered a reliable sterilization technique. To enhance microbial inactivation and prolong food shelf life, PEF can be used alongside mild heat treatments, other nonthermal processes, or antimicrobial packaging (Jin 2017; Balasubramaniam et al., 2022; Raso et al., 2022).

- PEF is a nonthermal method of food preservation

- Eliminates harmful microorganisms in liquid products through continuous flow processing

- Maintains superior product quality while improving energy efficiency due to low-temperature operation

One of PEF’s most important applications is preserving juices, smoothies, and purées without the quality losses associated with traditional heat pasteurization. Here’s why this matters:

Traditional heat pasteurization, while effective at killing harmful microorganisms, also degrades vitamins, changes flavors, and alters colors. PEF achieves the same microbial safety through electroporation while operating at much lower temperatures.

The results are impressive (Kantar et al., 2018 and Lee et al., 2024):

- Colors remain more vibrant over time

- Significant increase in juice yields and polyphenols in juice

- Fresh flavors and aromas are preserved

- Vitamins and beneficial compounds like polyphenols remain intact

- Heat-sensitive and thick products can be safely processed

- When combined with temperatures around 80°C, even bacterial spores can be eliminated

For consumers, this means chilled orange juice that tastes fresh for longer periods, and premium products that maintain their “just-squeezed” quality throughout their shelf life.

Transforming the Potato Industry

Since the first industrial PEF plant was installed in the French fries industry in 2010, this technology has become the new standard for potato processing (Mahathir, 2023 and Hill et.al. 2022). For example, the potato processing sector exemplifies PEF’s practical benefits. Companies producing French fries and potato chips have successfully implemented PEF to eliminate pre-heating steps traditionally required for cutting operations.

The technology reduces the force needed for slicing, extends cutting blade lifespan, improves product yields, enhances starch retention, minimizes breakage and oil absorption, reduces water consumption, and decreases acrylamide formation—all while consuming significantly less energy than the eliminated pre-heating processes. Research has demonstrated PEF’s ability to reduce freezing times for blanched vegetables by approximately 22%, potentially enabling higher throughput and lower energy consumption per unit of product.The transformation has been remarkable:

Preheating is used in french fry processing to reduce the brittleness of freshly harvested potatoes, minimizing slicing damage and improving the texture and appearance of the final product. Traditional potato processing required heating potatoes at 60°C for 40 minutes in pre-heaters (Andersson 1994, Laza et al., 2001)—an energy-intensive process that consumed enormous amounts of water and energy .

At an industrial level, McCain Foods has implemented a Pulsed Electric Field (PEF) system in its potato chip production, achieving significant benefits. The company reports saving around $1 million annually and reducing carbon emissions by nearly 3,990 tons each year. By using PEF instead of coal in the preheating stage, coal usage has decreased by seven tons daily, and freshwater consumption has been lowered by 82%. Additionally, the PEF technology has enhanced the cutting quality of the potatoes, leading to better utilization of the raw material (White et al., 2025).

During PEF treatment, potatoes can be processed either right after peeling and before cutting, or once they are already sliced. This process softens the tissue and makes it more flexible, significantly lowering resistance to mechanical actions like cutting. As a result, the cutting process becomes smoother, with fewer fractures or breakage. Furthermore, the microscopic pores formed by PEF increase the porosity of the potato tissue. When fried, this porous structure enables easier release of water and internal substances, which helps reduce oil absorption during cooking (Lee et al., 2024).

PEF processing accomplishes the same goals in just 10 seconds while using 90% less water and energy.

For that reason potato processors in the U.S., Canada, Europe, Australia, and New Zealand are adopting PEF pre-treatment to enhance cutting precision and minimize French fry breakage, offering a modern alternative to traditional preheating methods (Lee et al., 2023).

Benefits for French Fries:

- Reduced potato breakage during cutting by making potatoes more flexible

- 10% reduction in fat content due to improved cut quality. 10% reduction in oil absorption (major cost savings given chips contain up to 35% fat)

- 10% more starch retained in potatoes. Higher yields due to reduced starch loss

- 3-4% increase in overall yield from the same raw materials

- Equipment pays for itself in 6-18 months depending on the setup

- Improved crispiness

- Enhances drying efficiency.

- Significantly lighter-colored final products

A study demonstrated that using pulsed electric fields as a pre-treatment can effectively enhance the removal of acrylamide precursors from raw potatoes, leading to a reduced acrylamide content in deep-fried potato crisps. A reduction of 30% of acrylamide content was achieved after applying PEF (Genovese et al., 2019).

Frying is a complex process that involves heat, mass, and momentum transfer, all of which alter the food’s physical and chemical properties. Applying PEF treatment to plant-based foods can enhance these transfers, helping to control the Maillard reaction and support starch gelatinization. This emerging technology has been linked to several benefits in frying, including reduced oil absorption, lower levels of harmful compounds, and greater energy efficiency (Xu et al., 2020).

Since 2015, PEF has revolutionized chip production by solving a key quality issue. The treatment allows better washing of sugars from potatoes, preventing the brown coloring that occurs during frying (known as the Maillard reaction). This results in:

These advantages extend beyond regular potatoes to sweet potato, carrot, and cassava chips as well (Xu et al., 2020, Lee et al., 2023, Mahathir, 2023 and Hill et.al. 2022) .

The PEF advantages also extent to mashed potatoes. PEF processing in mashed potato production minimizes structural inconsistencies, leading to a smoother mash with fewer lumps and improved overall texture.

Revolutionizing Vegetable Processing

PEF benefits virtually every stage of vegetable processing:

Cutting and Preparation:

- Mushrooms: reduction in waste due to easier, more precise cutting

- Hard vegetables (beetroot, sweet potatoes): Significantly reduced blade wear

- Peeling (kiwis, tomatoes): Enhanced peelability through improved water migration

Blanching:

Traditional blanching—briefly boiling vegetables to inactivate enzymes—can be reduced by up to 50% with PEF pretreatment. In cases where blanching is only needed for softening, PEF can replace it entirely while providing precise texture control (Elea, 2025).

Drying Processes:

PEF dramatically improves all types of drying (hot air, vacuum, microwave, freeze-drying) by:

- Allowing faster water removal through enhanced internal transport

- Enabling either shorter drying times or lower temperatures

- Better preserving color, nutrients, and shape

- Facilitating easier rehydration of dried products

- Reducing cluster formation during freezing

Extracting Nature’s Valuable Components

PEF can enhance the extraction of valuable compounds like antioxidants, oils, and proteins from various food sources, including fruits, vegetables, and algae (Balasubramaniam et al., 2022; Razola-Díaz et al., 2023).

- Ruptures plant cell walls to boost extraction of juices, proteins, nutrients, vitamins, and natural pigments

- Reduces olive oil malaxation time and improves grape processing for wine production

- Creates nutrient-rich juices with higher yields while preserving color and vitamin content

The extraction capabilities of PEF technology have found widespread commercial adoption, particularly as demand for plant-based ingredients continues growing. By opening plant cells, PEF enables manufacturers to extract more nutrients and valuable components from the same raw material quantities, effectively increasing yield from existing resources.

Traditional extraction of valuable compounds from plants—whether pigments, vitamins, oils, or flavors—typically requires harsh mechanical grinding, high temperatures, or chemical solvents. PEF offers a gentler alternative that often achieves superior results (Chatzimitakos, 2023).

By opening cell membranes through electroporation, PEF enhances the natural movement of valuable substances out of cells. This works for extracting:

- Pigments and antioxidants

- Polyphenols and vitamins

- Natural oils and flavors

- Proteins and sugars

Example: Apple juice production shows the highest yields when using PEF compared to untreated fruit or even enzyme treatments. However, successful implementation requires careful consideration of downstream processing, as the softened plant material can sometimes affect pressing equipment.

In a nutshell PEF technology enables the efficient extraction of valuable compounds in less time, while also reducing solvent and energy usage, resulting in a more streamlined and effective process.

Wine Production Innovation

The wine industry has officially embraced PEF technology, with the International Organisation of Vine and Wine (OIV) approving it as an official cell disruption process for both red and white wines.

Red Wine Benefits:

- Faster color extraction: Traditional maceration takes 10-12 days; PEF reduces this to 5-6 days while achieving higher polyphenol concentrations

- Visual proof: PEF-treated samples show noticeably more intense red coloring

- Increased capacity: Shorter processing times mean higher production volumes

Fermentation Improvements:

- Accelerated flavor development: Compounds that normally take 180 days to fully develop reach maximum concentration in just 30 days

- Natural preservation: PEF can eliminate harmful microorganisms without adding sulfur dioxide

- Maintained quality: Dramatic time reductions don’t compromise wine quality standards

Premium Olive Oil Production

For extra virgin olive oil (EVOO)—the highest quality grade—producers face strict limitations: temperatures cannot exceed 27°C and no enzymes are permitted for cell disruption. PEF provides an ideal solution.

Traditional EVOO production achieves about 80% oil extraction efficiency. With PEF treatment (Siemer et al., 2024):

- Oil yields increase to 90-93% (a 10-13% improvement)

- Malaxation time and temperature can be reduced

- Enhanced polyphenol extraction improves antioxidant content

- Sensory quality improves—oils described as more fruity and full-bodied

- All while maintaining strict EVOO compliance standards

Meat Processing Innovations

PEF applications in meat processing offer benefits ranging from tenderization to improved marinading:

Tenderization:

- Works on any cut of meat from any species

- Even tough, collagen-rich cuts like beef brisket become tender without additives

- 17% reduction in cutting force required

- No chemicals, enzymes, or heavy mechanical processing needed

Processing Efficiency:

- Enhanced marinading: Faster and more complete absorption of brines and marinades

- Time and energy savings: Shorter tumbling times increase production capacity

- Raw sausage production: Accelerated fermentation, reduced drying time, and breakage-free slicing without affecting taste or color

Citrus and Fruit Processing

Citrus industry, particularly lemon, grapefruit and oranges, can benefit from PEF applications:

Juice Production:

- Preserve fresh taste and vitamin content in citrus juices

- Significant increase in juice yields and polyphenols in juice was obtained.

- Extend shelf life

- Maintain natural flavors without thermal damage

- Enable production of premium cold-pressed juices

Biotechnology Applications

PEF is revolutionizing how we extract valuable nutrients from microorganisms:

Yeast Processing:

Whether from brewing by-products or dedicated cultivation, yeast cells contain valuable flavors, proteins, and minerals. PEF extraction is both efficient and gentle, preserving the quality of these compounds.

Microalgae Cultivation:

Microalgae represent a sustainable source of bioactive compounds, proteins, and pigments for food and health industries. PEF offers several advantages:

- Selective extraction: Higher purity compared to ultrasound methods

- Quality improvement: Eliminates need for additional purification steps

- Stress response induction: Can actually stimulate microorganisms to grow faster or produce higher concentrations of desired compounds

This stress response effect also benefits starter cultures used in yogurt, salami, and other fermented foods.

The Future of Food Processing

PEF represents a fundamental shift toward more sustainable, efficient, and quality-preserving food processing. Unlike traditional methods that often force trade-offs between safety and quality, PEF frequently improves both simultaneously while reducing energy consumption and environmental impact.

As consumer demand grows for minimally processed foods that retain fresh-like qualities, and as sustainability concerns drive the need for more efficient processing methods, PEF technology is positioned to play an increasingly important role across the entire food industry.

From the French fries you eat to the juice you drink, from the wine you enjoy to the olive oil you cook with, PEF is quietly working behind the scenes to deliver better quality, safer products while using fewer resources. It’s not just an improvement in food processing—it’s a revolution in how we think about preserving and enhancing the foods we eat.

REFERENCES

Andersson, A., Gekas, V., Lind, I., Oliveira, F., Öste, R. and Aguilfra, J.M., 1994. Effect of preheating on potato texture. Critical Reviews in Food Science & Nutrition, 34(3), pp.229-251.

Balasubramaniam, V. M., Janahar, J., & Jin, T. (2022, November 9). Pulsed electric field processing applications in the food industry (Fact sheet No. FST‑FABE‑1002). Ohio State University Extension. Ohioline. Retrieved from https://ohioline.osu.edu/factsheet/fst-fabe-1002

Chatzimitakos, T., Athanasiadis, V., Kalompatsios, D., Mantiniotou, M., Bozinou, E., & Lalas, S. I. (2023). Pulsed Electric Field Applications for the Extraction of Bioactive Compounds from Food Waste and By-Products: A Critical Review. Biomass, 3(4), 367-401. https://doi.org/10.3390/biomass3040022

Demir, E., Tappi, S., Dymek, K., Rocculi, P., & Gómez Galindo, F. (2023). Reversible electroporation caused by pulsed electric field – Opportunities and challenges for the food sector. Trends in Food Science & Technology, 139, 104120. https://doi.org/10.1016/j.tifs.2023.104120

El Kantar, S., Boussetta, N., Lebovka, N., Foucart, F., Rajha, H.N., Maroun, R.G., Louka, N. and Vorobiev, E., 2018. Pulsed electric field treatment of citrus fruits: Improvement of juice and polyphenols extraction. Innovative Food Science & Emerging Technologies, 46, pp.153-161.

Elea PEF (2025), https://www.eleapef.com/#:~:text=Vegetables,breakage%2C%20and%20improves%20texture%20control.

Feng, Y., Yang, T., Zhang, Y., Zhang, A., Gai, L., & Niu, D. (2022). Potential applications of pulsed electric field in the fermented wine industry. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.1048632

Genovese, J., Tappi, S., Luo, W., Tylewicz, U., Marzocchi, S., Marziali, S., Romani, S., Ragni, L., & Rocculi, P. (2019). Important factors to consider for acrylamide mitigation in potato crisps using pulsed electric fields. Innovative Food Science & Emerging Technologies, 55, 18–26. https://doi.org/10.1016/j.ifset.2019.05.008

Ghoshal, G. (2023). Comprehensive review on pulsed electric field in food preservation: Gaps in current studies for potential future research. Heliyon, 9(6), e17532. https://doi.org/10.1016/j.heliyon.2023.e17532

Hill, K., Ostermeier, R., Töpfl, S., Heinz, V. (2022). Pulsed Electric Fields in the Potato Industry. In: Raso, J., Heinz, V., Alvarez, I., Toepfl, S. (eds) Pulsed Electric Fields Technology for the Food Industry. Food Engineering Series. Springer, Cham. https://doi.org/10.1007/978-3-030-70586-2_9

Jin Z. T., (2017) Food Safety and Intervention Technologies Research Unit, Eastern Regional Research Center, USDA, Wyndmoor, PA

Laza, M., Scanlon, M. G., & Mazza, G. (2001). The effect of tuber pre-heating temperature and storage time on the mechanical properties of potatoes. Food Research International, 34(8), 659–667. https://doi.org/10.1016/S0963-9969(01)00086-2

Lee, P.Y., Leong, S.Y. and Oey, I., 2024. Prospects of pulsed electric fields technology in food preservation and processing applications from sensory and consumer perspectives. International Journal of Food Science and Technology, 59(10), pp.6925-6943.

Mahathir, M. (2023, June 1). Reducing the impact. Food Science and Technology, 37(2), 46–49. https://doi.org/10.1002/fsat.3702_11.x

Mattar, J. R., Turk, M. F., Nonus, M., Lebovka, N. I., El Zakhem, H., & Vorobiev, E. (2015). S. cerevisiae fermentation activity after moderate pulsed electric field pre-treatments. Bioelectrochemistry, 103, 92–97. https://doi.org/10.1016/j.bioelechem.2014.08.016

Nowosad K, Sujka M, Pankiewicz U, Kowalski R. The application of PEF technology in food processing and human nutrition. J Food Sci Technol. 2021 Feb;58(2):397-411. doi: 10.1007/s13197-020-04512-4. Epub 2020 May 8. PMID: 33564198; PMCID: PMC7847884.

PEF for Potato Treatment., https://www.pulsemaster.us/pef-products/potato-products#:~:text=In%20potato%20processing%2C%20such%20as,%2C%20drying%2C%20and%20frying%20processes.

Polachini, T.C., Norwood, E.A., Le-Bail, P., Le-Bail, A. and Cárcel, J.A., 2023. Pulsed electric field (PEF) application on wheat malting process: Effect on hydration kinetics, germination and amylase expression. Innovative Food Science & Emerging Technologies, 86, p.103375.

Raso, J., Heinz, V., Álvarez, I., & Toepfl, S. (Eds.). (2022). Pulsed electric fields technology for the food industry: Fundamentals and applications (2nd ed.). Springer International Publishing. https://doi.org/10.1007/978-3-030-70586-2

Razola-Díaz, M. del C., Tylewicz, U., Rocculi, P., & Verardo, V. (2023). Chapter Eight – Application of pulsed electric field processing in the food industry. In S. M. Jafari & N. Therdthai (Eds.), Non-thermal food processing operations (pp. 257–298). Woodhead Publishing. https://doi.org/10.1016/B978-0-12-818717-3.00009-3

Siemer, C., Hill, K., Schröder, S., Kirchner, M., & Töpfl, S. (2024, February). Application of pulsed electric fields (PEF) in the food industry (2nd ed., DLG Expert Report 02/2024). DLG e.V. https://www.dlg.org/en/mediacenter/dlg-expert-reports/nutrition/dlg-expert-report-02-2024-application-of-pulsed-electric-fields-pef-in-the-food-industry

Stühmeier-Niehe, C., Lass, L., Brocksieper, M., Chanos, P., & Hertel, C. (2023). Pre-Treatment of Starter Cultures with Mild Pulsed Electric Fields Influences the Characteristics of Set Yogurt. Foods, 12(3), 442. https://doi.org/10.3390/foods12030442

Tomasevic, I., Heinz, V., Djekic, I., & Terjung, N. (2023). Pulsed electric fields and meat processing: latest updates. Italian Journal of Animal Science, 22(1), 857–866. https://doi.org/10.1080/1828051X.2023.2206834

White, S., Jackson-Davis, A., Gordon, K., Morris, K., Dudley, A., Abdallah-Ruiz, A., Allgaier, K., Sharpe, K., Yenduri, A. K., Green, K., & Santos, F. (2025). A review of non-thermal interventions in food processing technologies. Journal of Food Protection, 88(6), 100508. https://doi.org/10.1016/j.jfp.2025.100508

Xiang Li, Mohammed Farid, 2016. A review on recent development in non-conventional food sterilization technologies. https://doi.org/10.1016/j.jfoodeng.2016.02.026

Xu Z, Leong SY, Farid M, Silcock P, Bremer P, Oey I. Understanding the Frying Process of Plant-Based Foods Pretreated with Pulsed Electric Fields Using Frying Models. Foods. 2020 Jul 17;9(7):949. doi: 10.3390/foods9070949. PMID: 32709057; PMCID: PMC7404407.