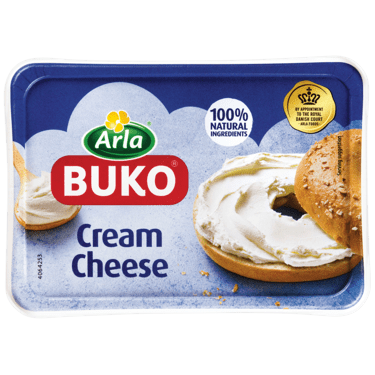

ARLA’S BUKO CREAM CHEESE IS A spot-on example that directly addresses the question above

Arla Foods’ Holstebro Dairy produces Buko cream cheese and depends on a minimum packing temperature of 68°C. In the past, the plant used steam-driven scraped surface heat exchangers that heated the product to 78°C, creating an unnecessary 10°C safety margin and wasting energy. If the temperature drops below 68°C during packing, then the cheese is too cold for packaging and consequently it needs to be reheated back to 78°C, leading to even greater inefficiency.

The solution was ohmic heating. By pumping the cream cheese through a pipe and applying an electric current, the system leverages the product’s natural resistance to generate heat. This method delivers 96% efficiency and maintains the cheese at precisely 68°C with an accuracy of ±0.3°C. As a result, the company eliminates the 10°C excess heating and avoids costly downtime from temperature drops. Altogether, this improvement has provided production gains equal to an extra week of output each year.

The business case remains attractive even without considering energy savings, since the optimized process now avoids frequent stoppages. Beyond that, extra savings come from eliminating the need to reach steaming temperatures of up to 90 °C. Although the ohmic heating system relies on electricity, total energy use is lower because far less steam heating is required (Alflow Scandinavia, 2025a). That was a clear demonstration of the right answer to the question above.

Another example

Kerry Ingredients & Flavours Group transforms large amounts of surplus cheese, which might otherwise go to waste, into valuable products like cheese powder. Their goal was to identify a heating method that is more efficient, gentle, and sustainable than conventional steam heating.

To make cheese powder, the process generally follows the key steps shown in the flow diagram (Deshwal, Akshit, Altay, & Huppertz, 2024):

- Selection and preparation of cheese – cheeses are minced or cut into cubes.

- Mixing with other ingredients – such as water, calcium salts, and emulsifiers.

- Blending and heating – the mixture is homogenized and then heated.

- Sieving – separating undissolved mass from the smooth cheese emulsion.

- Spray drying – turning the emulsion into cheese powder.

- Packaging and storage.

Traditionally, the heating step is carried out using steam. However, Kerry Ingredients has introduced ohmic heating as a replacement. Instead of using steam, ohmic heating passes an electric current directly through the cheese mixture, which heats it quickly and evenly.

Benefits of ohmic heating in cheese powder production:

- No steam = no dilution, so less drying is needed.

- More stable flow and uniform temperature.

- Higher dry matter content in the cheese mix.

- Gentler treatment reduces the risk of lumps.

- Shorter cleaning time (saves one hour per cycle).

- Lower energy consumption and improved sustainability.

- Higher quality cheese powders

In short, ohmic heating fits into the heating stage of cheese powder production and makes the process more efficient, sustainable, and product-friendly compared to traditional steam heating (Alflow Scandinavia, 2025b).

Proactive Food Processing Optimization

Optimizing food processing is a continuous process that should be done proactively, not just when issues arise. It’s crucial for efficiency, sustainability, and food safety. This optimization should happen throughout the entire production process, from ingredient sourcing to packaging and distribution. While food safety remains a top priority, food and drink manufacturers face increasing pressure to produce not only safe food, but also to produce it as cost-effectively and efficiently as possible.

Optimizing thermal processes—finding the ideal balance of time and temperature—can play a key role in achieving these goals. However, determining the right minimum safe process for your specific product can be complex. Factors such as the unique characteristics of different foods, which may make some more vulnerable to spoilage or pathogen growth than others, add to the challenge.

To help deepen your understanding of process optimisation, we’ll explore four key scenarios where reviewing and refining your approach may be necessary:

- Before scaling up or introducing new products

Optimize your processes before making significant changes to ensure smooth and efficient production. - Processes That Go Too Far

When thermal treatments are more intense than necessary, they can compromise the flavour, texture, or appearance of the product—while also wasting energy. Right-sizing the process not only protects quality but boosts sustainability. - Products That Shield Microorganisms

Some foods have natural traits that can protect harmful microorganisms, making them harder to eliminate with standard processing. These products often require a tailored approach to ensure safety. - When Using Low-Temperature Treatments

Certain products or requirements call for gentler thermal processing. In these cases, it’s crucial to back your approach with strong data to prove that even under worst-case conditions, safety is maintained. - After a Process Failure

If a product fails to meet safety or quality expectations, it’s vital to reassess the processing parameters. Establishing the correct minimum safe process ensures compliance and consistency moving forward. Regularly evaluate your processes to pinpoint areas where improvements can be made. - When new technologies or regulations emerge

Stay informed about advancements in food science and technology and adapt your processes accordingly.

Food production should be viewed as a dynamic process that requires ongoing monitoring and improvement. Food Safety comes first, but how far would you go?

Key Takeaways

- Efficiency and Cost Reduction

Optimizing reduces waste, improves resource utilization (energy, water), and enhances overall efficiency, leading to lower production costs. - Safety and Efficiency Must Go Hand in Hand

It’s not enough to ensure your product is safe—your processes should also be lean, cost-effective, and aligned with quality goals. - Let the Data Drive Decisions

A science-based approach is crucial. Robust data helps you validate your processes and make informed adjustments, especially when dealing with challenging products or non-standard treatments. - Meeting Market Demands Staying ahead of trends and adapting to changing consumer preferences requires optimized processes.

- Quality Shouldn’t Be a Trade-Off

Overprocessing might ensure safety, but it can harm the sensory appeal of your product and lead to energy waste. Striking the right balance is key. - Continuous Improvement is Essential

Process optimisation isn’t a one-off task. Regularly reviewing and refining your methods keeps you ahead of potential risks and aligned with evolving industry standards.

Reference:

lflow Scandinavia (2025a). Arla Foods achieves an extra week of production with ohmic heating. Alflow. Retrieved October 19, 2025, from https://www.alflow.dk/en/cases/arla-foods-achieves-an-extra-week-of-production-with-ohmic-heating.

Alflow Scandinavia (2025b). Kerry turns waste into value – with ohmic heating. Retrieved October 19, 2025, from https://www.alflow.dk/en/cases/kerry-turns-waste-into-value-with-ohmic-heating/.

Deshwal, G. K., Akshit, F. N. U., Altay, I., & Huppertz, T. (2024). A review on the production and characteristics of cheese powders. Foods, 13(14), 2204. https://doi.org/10.3390/foods13142204.